Services

What we do

Top services

With over 45 years of hands-on experience in the injection molding industry, I bring a wealth of knowledge and a deep understanding of the complexities involved in injection molding processes. My career spans custom injection mold builders, custom injection molders, and proprietary injection molders across various industries such as consumer goods, automotive (working with brands like BMW, Honda, GE Appliances, Motorola and Tesla), and recreational products. I’ve developed a solid reputation for delivering precision, efficiency, and results through expert consulting. Whether your business requires in-person support or remote assistance, I offer a comprehensive range of services tailored to improve your operations and reduce costs.

Quoting & Sourcing

From material selection to cost estimations, our quoting and sourcing services provide you with the information you need to make informed decisions. We tap into our global network of suppliers to ensure you have access to the best resources at competitive prices.

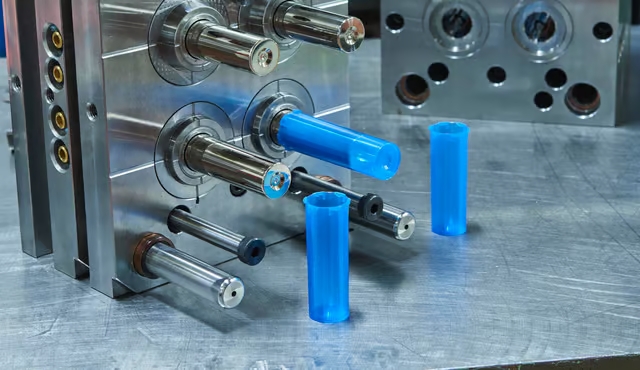

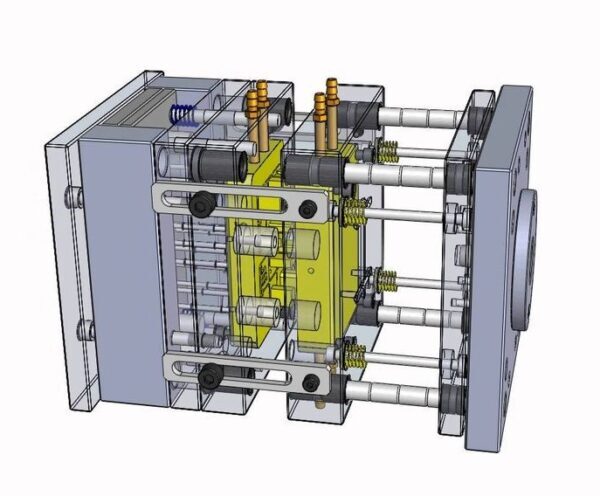

Mold Design Reviews

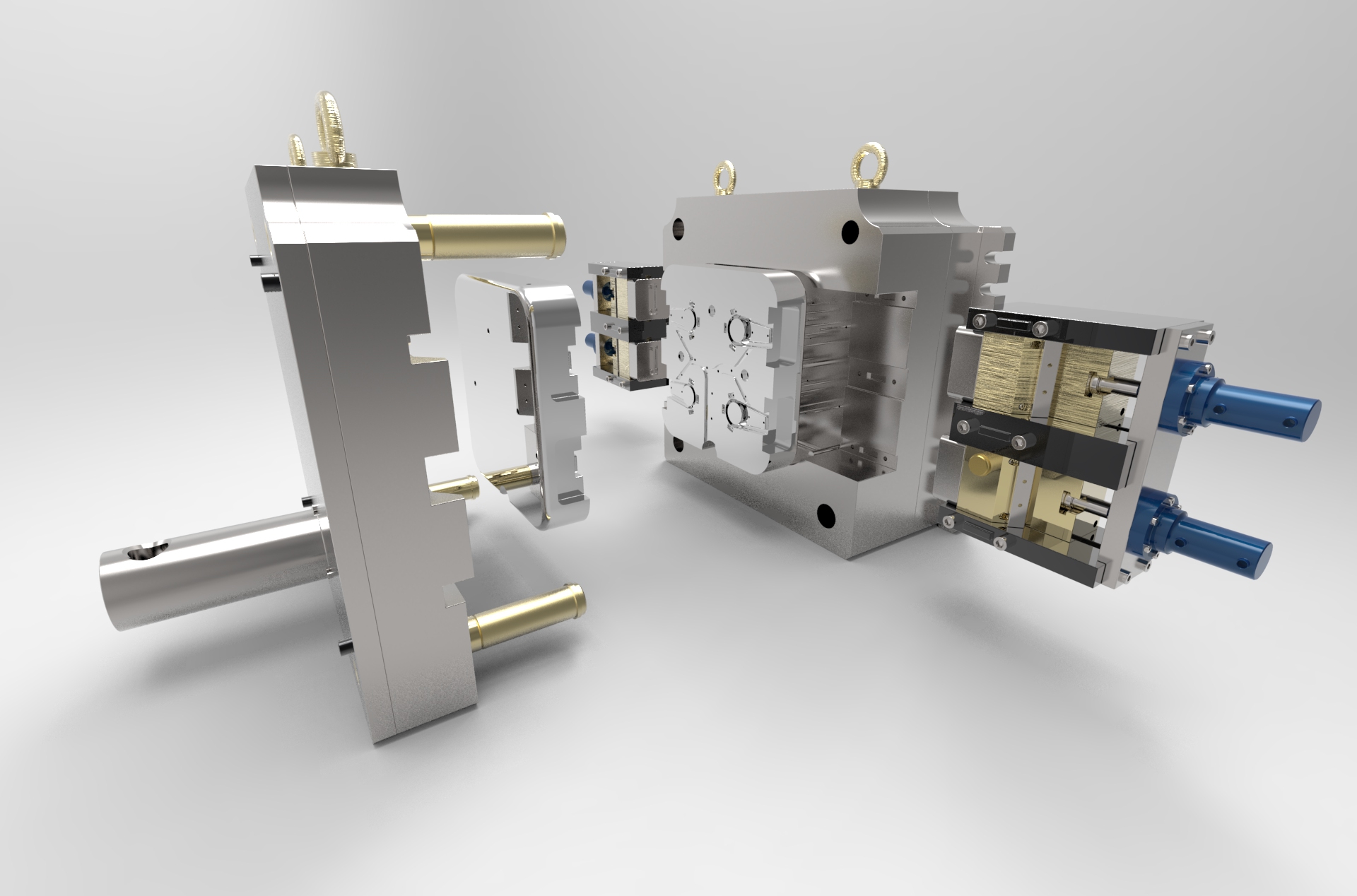

Our team conducts rigorous design reviews to ensure that your molds are production-ready and optimized for performance. We identify potential issues before they become costly mistakes, helping you save time and money.

Consulting Services

Whether you’re launching a new product or optimizing an existing design, our consulting services provide actionable insights that will streamline your production process and improve the overall quality of your molds.

Quoting Injection Molds

Accurate quoting is critical to the success of any project. With my extensive experience, I can help you generate precise and competitive quotes for injection molds. By considering material costs, complexity, and production timelines, I ensure that your quotes are realistic and aligned with market standards, helping you make informed decisions and secure your projects.

Sourcing Injection Molds

Finding the right mold supplier can be challenging, especially with the need for quality, reliability, and cost-efficiency. I can assist you in sourcing high-quality injection molds from trusted manufacturers, leveraging my industry connections and deep knowledge of the market. Whether you’re looking for local or international suppliers, I’ll help you identify the best fit for your specific requirements, ensuring quality without sacrificing efficiency or budget.

Reviewing Preliminary Mold Designs

The foundation of a successful molding process lies in a well-thought-out design. I offer detailed reviews of your preliminary mold designs to ensure that they are optimized for production and free of potential flaws. My reviews focus on design feasibility, manufacturability, and cost-effectiveness, ensuring that you avoid costly mistakes and delays later in the production cycle.

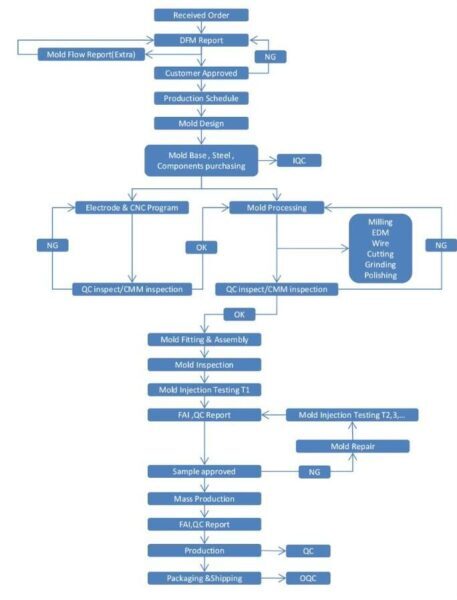

DFM (Design for Manufacturability) Reviews

A well-executed DFM review is crucial in preventing production issues and optimizing design for cost-effective manufacturing. I will conduct a thorough DFM analysis, focusing on simplifying part design, minimizing production costs, and ensuring that your parts are engineered for optimal manufacturability. This process helps in reducing material waste, improving mold longevity, and streamlining production.

Reviewing Mold Flow Reports

Mold flow analysis is essential to predicting how material will behave during the injection process, ensuring parts meet the desired quality standards. I analyze mold flow reports to identify any potential issues, such as warping, sink marks, or fill imbalances, which could affect the final product’s quality or lead to production inefficiencies. My goal is to ensure that your parts are produced with the highest level of precision and consistency.

Approving Mold Designs Before Cutting Steel

Cutting steel is one of the most critical and expensive steps in the mold production process. Before this irreversible stage, I offer expert approval of mold designs, ensuring that every detail has been meticulously reviewed. My experience allows me to catch any potential issues in the design that could result in production delays or quality problems. By approving your designs before cutting steel, I help you avoid unnecessary adjustments, saving both time and money.

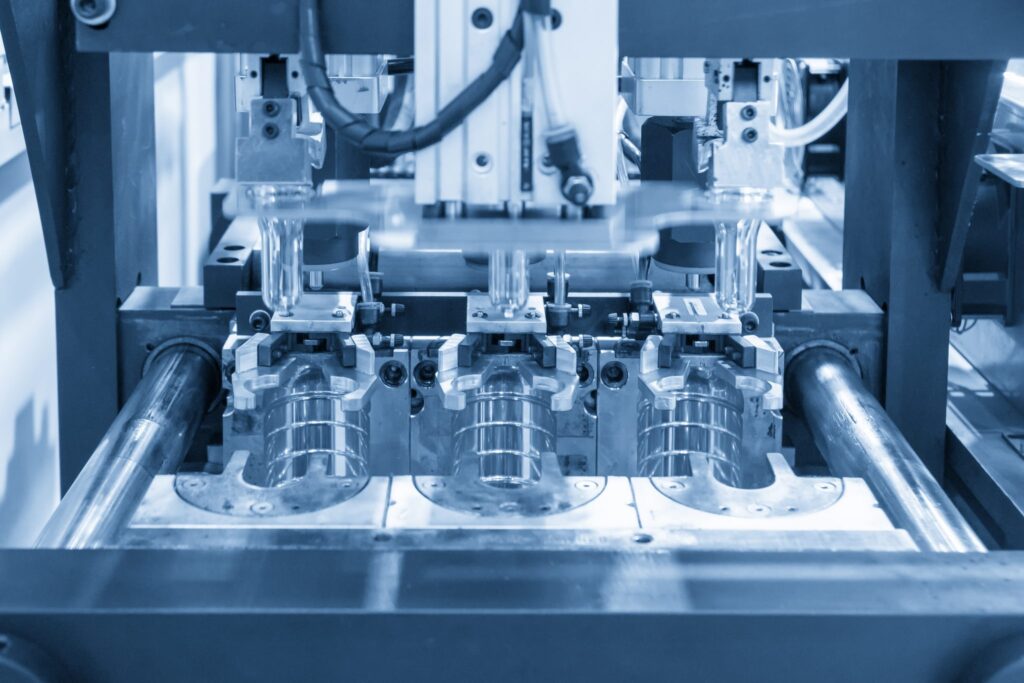

Reducing Molding Cycle Times and Costs

Cycle time has a direct impact on production efficiency and profitability. With decades of experience optimizing molding processes, I specialize in identifying ways to reduce cycle times, increase production throughput, and minimize costs. Whether it’s through material selection, design adjustments, or process optimization, I can help you make the necessary improvements to reduce your production time without compromising on quality.

Improving Cycle Times

Beyond just reducing cycle times, I work closely with your team to fine-tune the entire injection molding process. This involves examining factors like cooling times, material flow, machine settings, and automation opportunities. The end result is a streamlined process that not only improves cycle times but also enhances overall efficiency and output, allowing you to meet production goals faster.

Reviewing the Process Flow at Your Facility

An efficient process flow is key to maintaining productivity and reducing downtime. I provide a comprehensive review of your facility’s process flow, evaluating each step of the production line to identify bottlenecks and inefficiencies. My recommendations are tailored to help you improve the movement of materials, reduce lead times, and optimize overall workflow. By improving your facility’s process flow, you can reduce waste, increase efficiency, and ultimately improve your bottom line.

Consulting Services

Consulting Services

Production

Quoting & Sourcing

Mold Design Reviews

contact us

Have a project?

Send a brief!

Ready to take your injection mold designs to the next level? Contact us today for a free consultation and see how BG Innovations LLC can help your business thrive. Click here to schedule your consultation or call us at 864-381-1920 for more information.

Corporate Service

Top engineering for every project

Our team offers specialized services in quoting, sourcing, and mold design reviews. Each project is a partnership, and we work closely with you to ensure your molds meet the highest standards in terms of efficiency, accuracy, and functionality. This client-first approach has earned us the trust of leading brands and companies across a variety of industries.

Quoting &

Sourcing

Read More

Mold Design

Reviews

Read More

Consulting

Services

Read More

Our Values

BG Innovations LLC Values

At BG Innovations LLC, we believe in three core values: quality, innovation, and partnership. These values drive everything we do, from the way we interact with our clients to the solutions we provide.

- Quality: We are committed to delivering high-quality solutions that meet the needs of our clients. We hold ourselves to the highest standards of excellence and are constantly striving to improve.

- Innovation: The world of injection molding is always evolving, and we pride ourselves on staying ahead of the curve. We’re constantly exploring new technologies and techniques to ensure that our clients receive the most innovative solutions available

- Partnership: We view every client as a partner. Your success is our success, and we’re committed to building lasting relationships that help your business thrive.